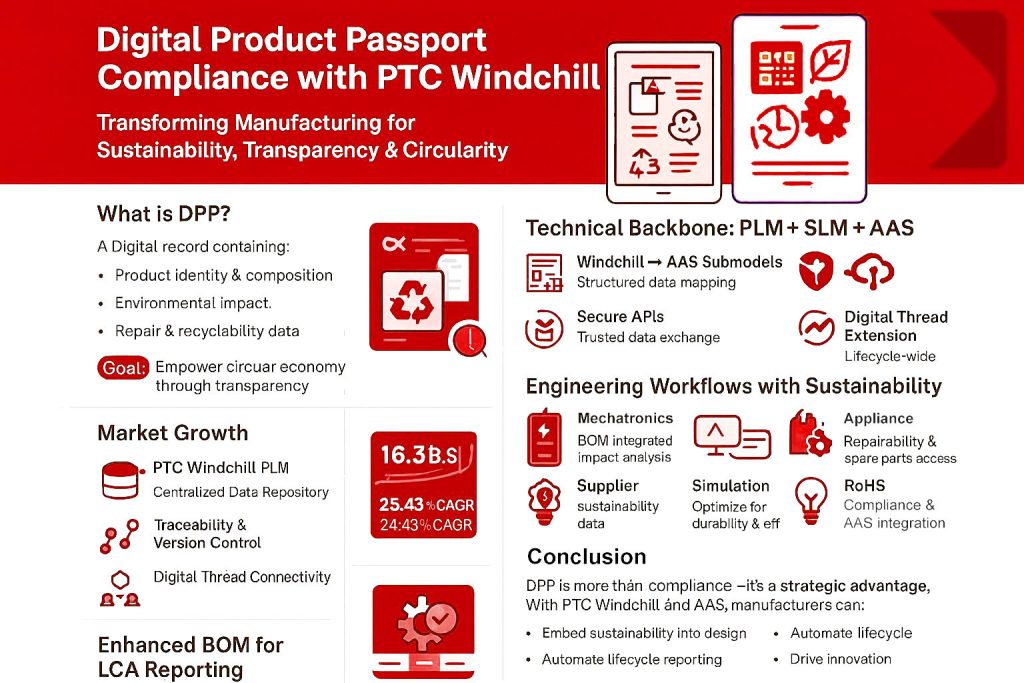

The manufacturing landscape is undergoing a significant transformation driven by increasing demands for sustainability, transparency, and circularity. A key initiative at the forefront of this change is the Digital Product Passport (DPP), a digital record of a product's journey from conception to end-of-life. For manufacturers, navigating the complexities of DPP compliance presents both challenges and opportunities. This article explores how leveraging PTC Windchill, with its robust data integration standards and digital thread connectivity, can be used to build a comprehensive and efficient DPP compliance solution, especially when integrated with the Asset Administration Shell (AAS) standard.

1. What is DPP Compliance?

A Digital Product Passport (DPP) is an electronic record containing information about a product's identity, composition, origin, environmental impact, and repair/recyclability potential. Its primary goal is to foster a circular economy by providing stakeholders—from consumers to recyclers—with easy access to crucial product information. This transparency enables informed purchasing decisions, facilitates sustainable practices, and streamlines end-of-life management.

2. Market Growth

The market for DPP solutions is experiencing rapid growth, driven by regulatory mandates and a global shift toward circular economy principles. The global digital product passport market is projected to grow from $2.4 billion in 2025 to approximately $10.8 billion by 2035, exhibiting a compound annual growth rate (CAGR) of 16.3%. Other sources forecast the market to reach $23.14 billion by 2034, with a CAGR of 24.43%.

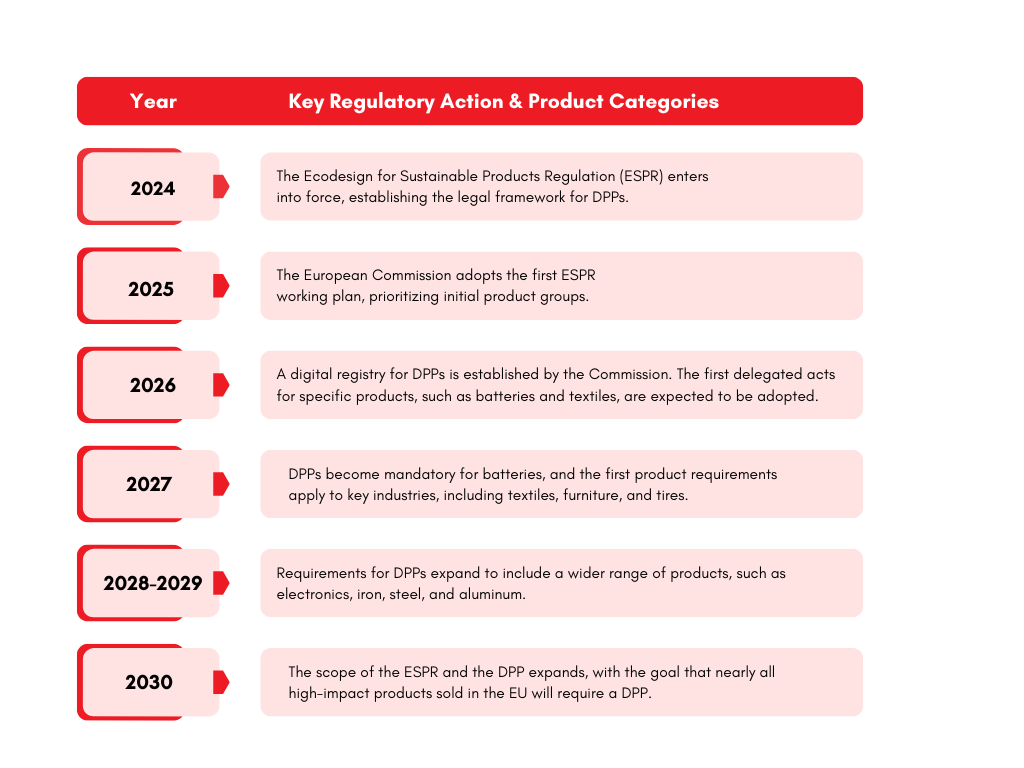

3. Regulatory Timeline

The European Union is at the forefront of DPP implementation through its Ecodesign for Sustainable Products Regulation (ESPR). The timeline for mandatory DPPs is phased and will apply to different product categories over the coming years.

1. Why PLM is the Natural Solution

Product Lifecycle Management (PLM) systems like PTC Windchill are inherently positioned as the ideal foundation for DPP compliance. PLM is designed to manage all product-related information throughout its entire lifecycle, from ideation and design to manufacturing, service, and end-of-life. This comprehensive data management capability directly aligns with the core requirements of a DPP.

A robust PLM system offers:

- Centralized Data Repository: A single source of truth for all product data, including CAD models, BOMs, specifications, manufacturing processes, and supplier information.

- Traceability and Version Control: The ability to track changes and versions of product data, ensuring accuracy and auditability.

- Digital Thread Connectivity: Connecting various disciplines and systems across the product lifecycle, from engineering to manufacturing and service.

- Collaboration and Workflow Management: Facilitating seamless collaboration among diverse teams and managing the processes involved in product development.

By leveraging these capabilities, PLM minimizes data silos, reduces manual efforts, and ensures the integrity of the information required for a compliant DPP.

2. Technical Approach

The technical backbone of a successful DPP solution built on PTC Windchill involves a strategic integration of PLM and Service Lifecycle Management (SLM) with the Asset Administration Shell (AAS) standard. This approach provides a standardized, interoperable framework for exchanging product information.

3. PLM and SLM Integrations with AAS Standards:

The Asset Administration Shell (AAS) is a standardized digital twin concept that enables interoperable information exchange across different systems and companies. Integrating PTC Windchill with AAS involves:

- Mapping Windchill Data to AAS Submodels: Key product data residing in Windchill (e.g., material composition, manufacturing locations, repair instructions) can be mapped to specific submodels within the AAS. This ensures that the information is structured and accessible in a standardized format.

- Establishing Secure Data Exchange: Utilizing secure APIs and communication protocols to enable seamless and trusted exchange of AAS data with external platforms, regulatory bodies, and supply chain partners.

- Leveraging the Digital Thread: Windchill's digital thread capabilities can be extended to encompass the AAS, providing a continuous flow of updated product information throughout its lifecycle, from design to service and end-of-life.

4. Enhanced BOM Management for Reliable LCA Reporting:

The Bill of Materials (BOM) is a critical component for DPP and Life Cycle Assessment (LCA) reporting. Enhanced BOM management within Windchill for DPP compliance includes:

• Sustainability Attributes in BOM: Extending the BOM to include sustainability-related attributes such as material origin, recycled content percentage, hazardous substance declarations, and energy consumption of components.

• Supplier Data Integration: Connecting directly with supplier databases to automatically pull in environmental performance data and certifications for individual components.

• AI for Predictive LCA Data and Analysis: Integrating AI and machine learning algorithms directly into Windchill to predict the environmental impact of design choices and material selections during the product development phase. This allows engineers to assess the LCA implications of different options in real-time, enabling proactive optimization for sustainability.

• Automated LCA Report Generation: Generating automated LCA reports based on the enriched BOM data and predictive AI insights, significantly reducing the manual effort and time required for compliance.

5. Integration of Sustainability Metrics into Engineering Workflows:

To truly embed sustainability into product development, it needs to be integrated into daily engineering practices.

• Mechanical Engineering: Integrating sustainability metrics directly into CAD systems (e.g., Creo) to allow engineers to analyze the environmental impact of different designs and material choices in real-time.

• Electrical Design: Incorporating sustainability considerations into electrical design tools (e.g., PTC Creo Schematics, ECAD integrations) to assess power consumption, material composition of PCBs, and end-of-life implications of electronic components.

• Simulation Workflows: Using simulation tools (e.g., Creo Simulate, ANSYS integrations) to optimize designs for durability, reparability, and material efficiency, thus reducing waste and extending product lifespan.

________________________________________

Here are three simple case studies illustrating how PTC Windchill can facilitate DPP compliance:

1. Battery Manufacturing

• Challenge: The EU Battery Regulation mandates detailed DPPs for industrial and electric vehicle batteries, requiring information on material composition, recycled content, carbon footprint, and performance data.

• Windchill Solution:

o Enhanced BOM: Windchill manages a comprehensive BOM for each battery, including detailed material breakdowns (e.g., lithium, cobalt, nickel percentages), origin of raw materials, and recycled content declarations.

o Sustainability Data Integration: Supplier certificates for raw material sustainability and carbon footprint data are directly linked to BOM components in Windchill.

o Manufacturing Process Data: Windchill records manufacturing process parameters and energy consumption data associated with battery production.

o Performance Tracking: Integration with test systems feeds battery performance metrics and expected lifespan into Windchill.

o AAS Integration: All this data is aggregated and published as an AAS for the battery, accessible via a QR code on the physical product, enabling stakeholders (recyclers, consumers) to access crucial information for safe handling, reuse, and recycling.

o AI for Predictive LCA: AI models in Windchill predict the lifecycle carbon footprint based on design variations, allowing engineers to choose materials and designs with lower environmental impact.

2. Textile Industry

• Challenge: The textile industry faces demands for transparency on fiber composition, chemical use, ethical sourcing, and recyclability to combat fast fashion and promote circularity.

• Windchill Solution:

o Product Definition: Windchill stores detailed product specifications for each garment, including fiber types (e.g., organic cotton, recycled polyester), dyeing processes, and finishing treatments.

o Supply Chain Traceability: Integration with supplier management systems in Windchill tracks the origin of raw materials (e.g., cotton farms, dyeing facilities) and certifies fair labor practices.

o Chemical Management: Information on restricted substances used in manufacturing is managed and linked to each product within Windchill.

o Repair & Recycling Instructions: Detailed instructions for care, repair, and end-of-life recycling are captured and maintained.

o AAS Generation: A DPP (as an AAS) is generated for each textile product, providing consumers with scannable access to ethical sourcing information, care instructions, and guidance for recycling or donation. This also includes information on the product's embedded water and energy footprint, driven by enhanced BOM data.

3. Appliance Manufacturing

• Challenge: Manufacturers of white goods (e.g., washing machines, refrigerators) need to provide information on energy efficiency, repairability, spare part availability, and hazardous materials.

• Windchill Solution:

o Design for Repairability: Windchill manages the design data, ensuring easy access to spare parts lists, service manuals, and disassembly instructions.

o Energy Efficiency Data: Performance data from testing, including energy consumption ratings, is linked to the product definition in Windchill.

o Material Declarations: Detailed material composition, including the presence of any restricted substances (e.g., RoHS compliance), is stored in the BOM.

o Spare Parts Management: Integration with Service Lifecycle Management (SLM) solutions ensures that information on spare part availability and obsolescence is readily accessible.

o AAS for Appliances: A DPP (AAS) for each appliance provides consumers and service technicians with information on energy ratings, expected lifespan, repair guides, and where to find spare parts, extending the product's useful life. AI-driven insights could also highlight optimal maintenance schedules to further reduce energy consumption.

________________________________________

Conclusion

The Digital Product Passport is not just a regulatory hurdle; it's a catalyst for innovation and a cornerstone of the circular economy. By establishing a digital twin approach via the Asset Administration Shell and leveraging the robust data management capabilities of PTC Windchill, manufacturers can transform compliance into a competitive advantage. The deep integration of sustainability metrics into engineering workflows, coupled with AI-driven predictive LCA analysis and enhanced BOM management, ensures that environmental considerations are not an afterthought but an integral part of product development. This proactive approach not only streamlines DPP compliance but also drives genuine sustainability improvements, strengthens brand reputation, and unlocks new opportunities for product innovation and customer engagement.

For tailored consulting solutions to navigate your Digital Product Passport journey and optimize your PTC Windchill implementation, contact Accrevent today.